CNC Milling

12/04/2021

make (design+mill+assemble) something big (~meter-scale)

extra credit: don't use fasteners or glue

extra credit: include curved surfaces

This week took me forever to come up with an idea for. I think I only landed on this idea on the Wednesday it was due :). So this entire project was done after the normal date. But I'm happy with the idea and how it turned out.

Designing

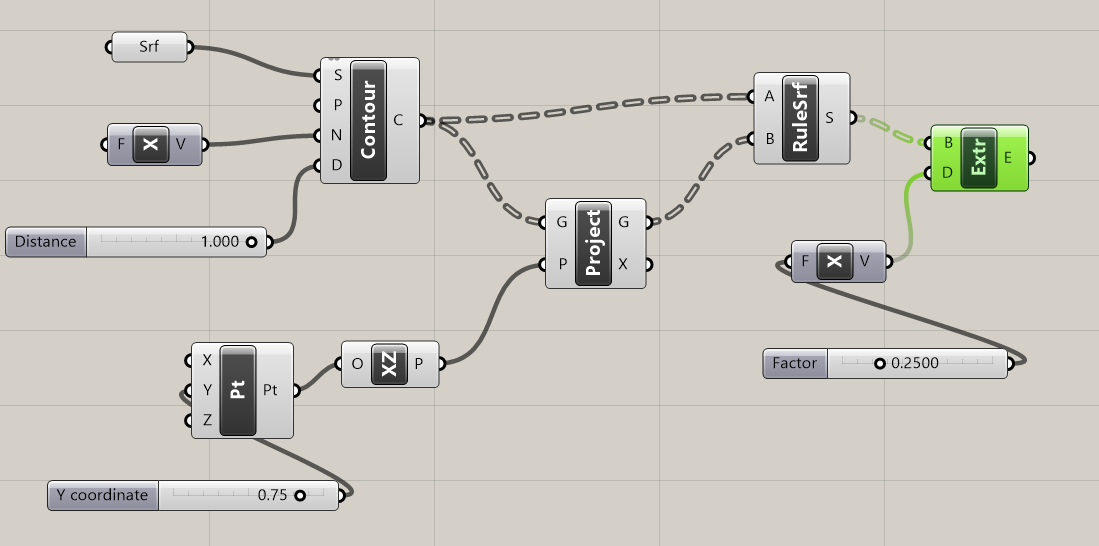

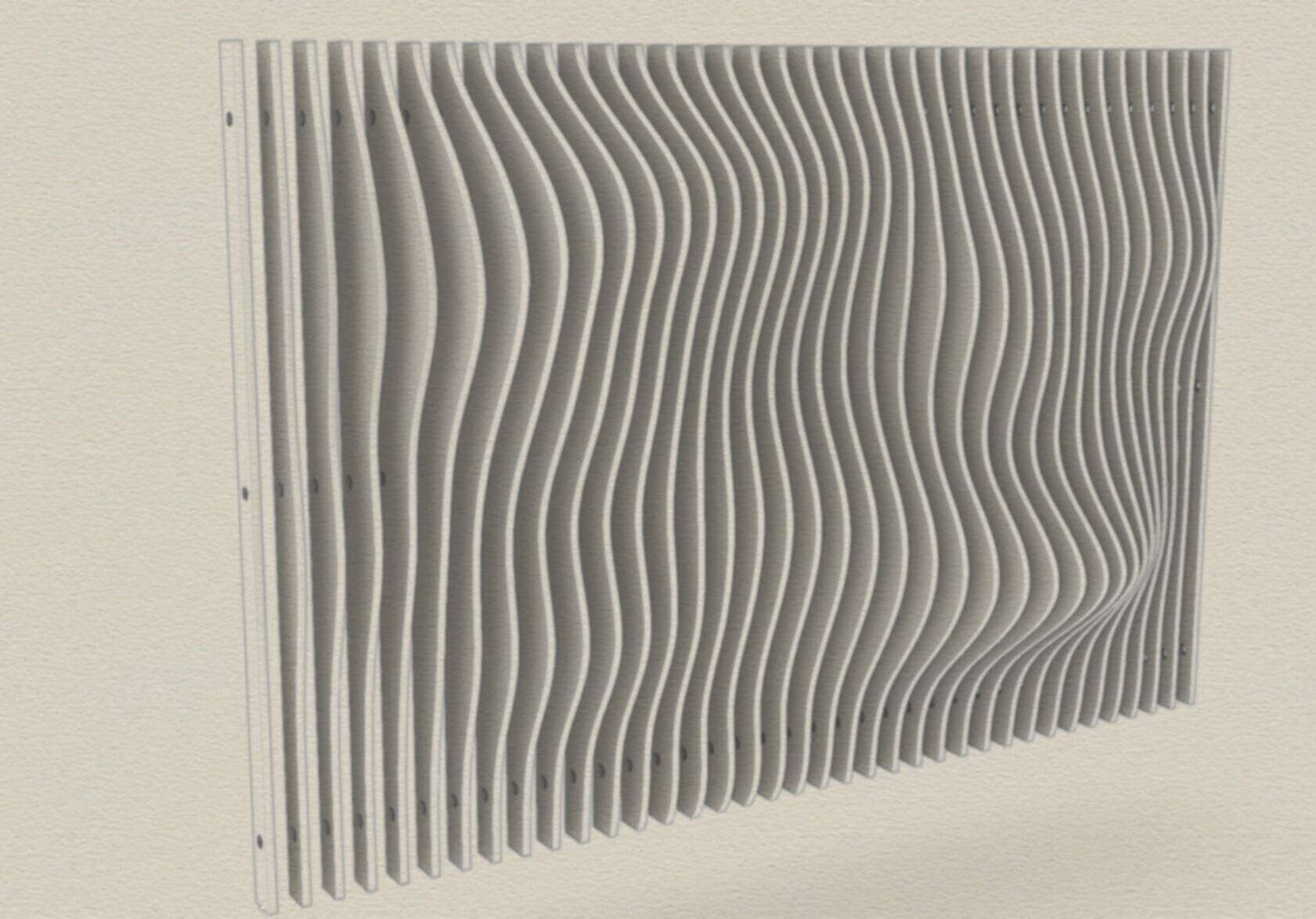

I wanted to learn out to use Rhino because I had seen the architecture students using it a bunch and it seemed pretty powerful. I'm a SolidWorks guy, so being able to do anything with curves would be pretty impressive. Rhino also has this thing called Grasshopper where you can set up a chain of function to programmatically form a surface. Since I was completely new to it, I was wondering how I could CAD my wavy structure, but luckily I found a youtube video on exactly what I needed.

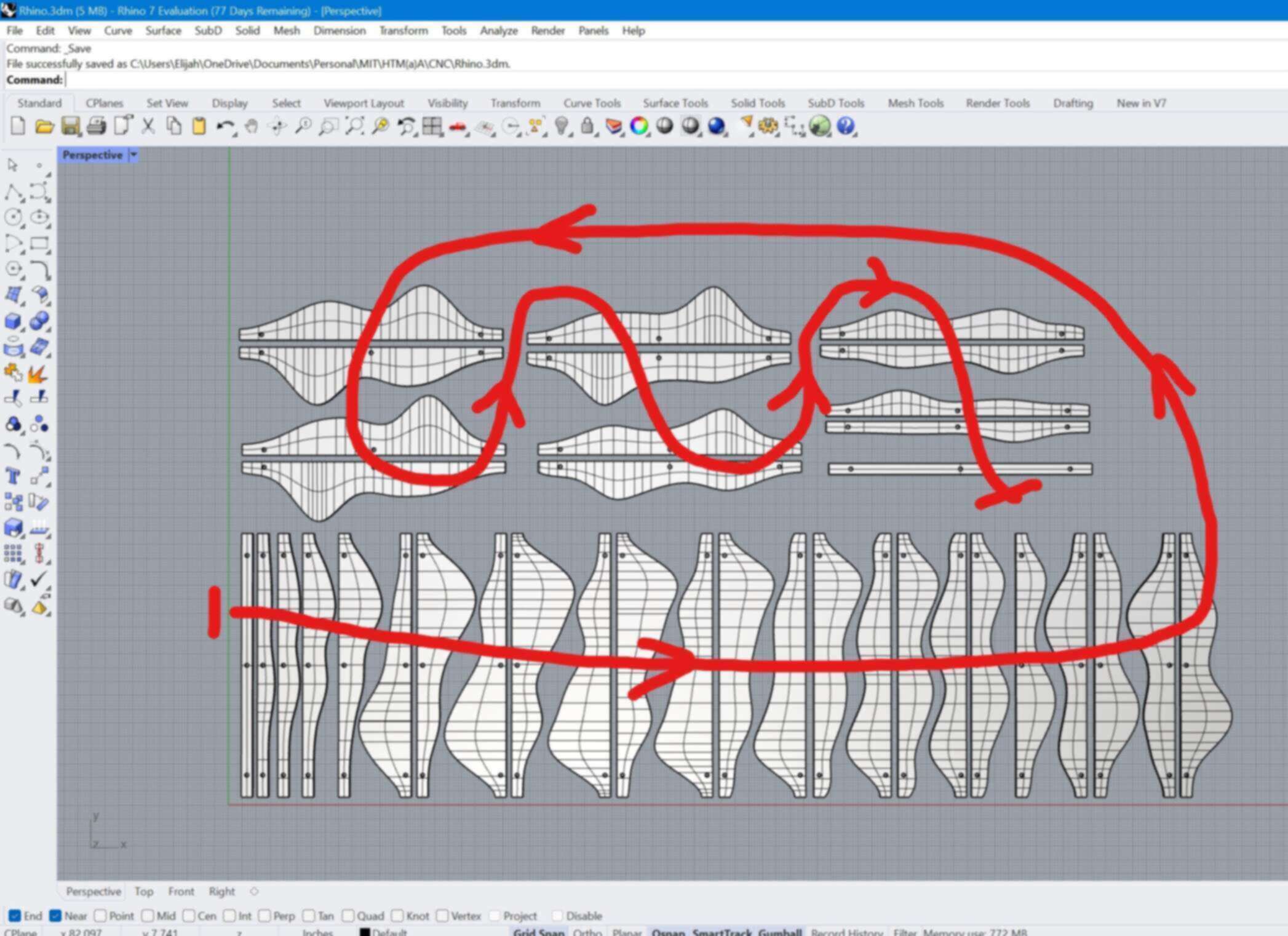

After consulting with a random very nice person in the archshop, I separated all the pieces and moved them so that they would fit in the 4' by 8' OSB sheet. For my future reference(which I didn't need) I drew an arrow over which way to assemble it. The standoffs are missing in this image.

Cutting

After setting up a time to meet in N51 I got to behold the glory of the Onsrud. It's a truely amazing machine

The guy in the shop helped me set up my file in MasterCam to be milled. We then headed over to the Onsrud and he got the machine started and told me to watch over it to make sure nothing went wrong. He forgot to lower the dust guard down immediately, so I got to grab this cool video.

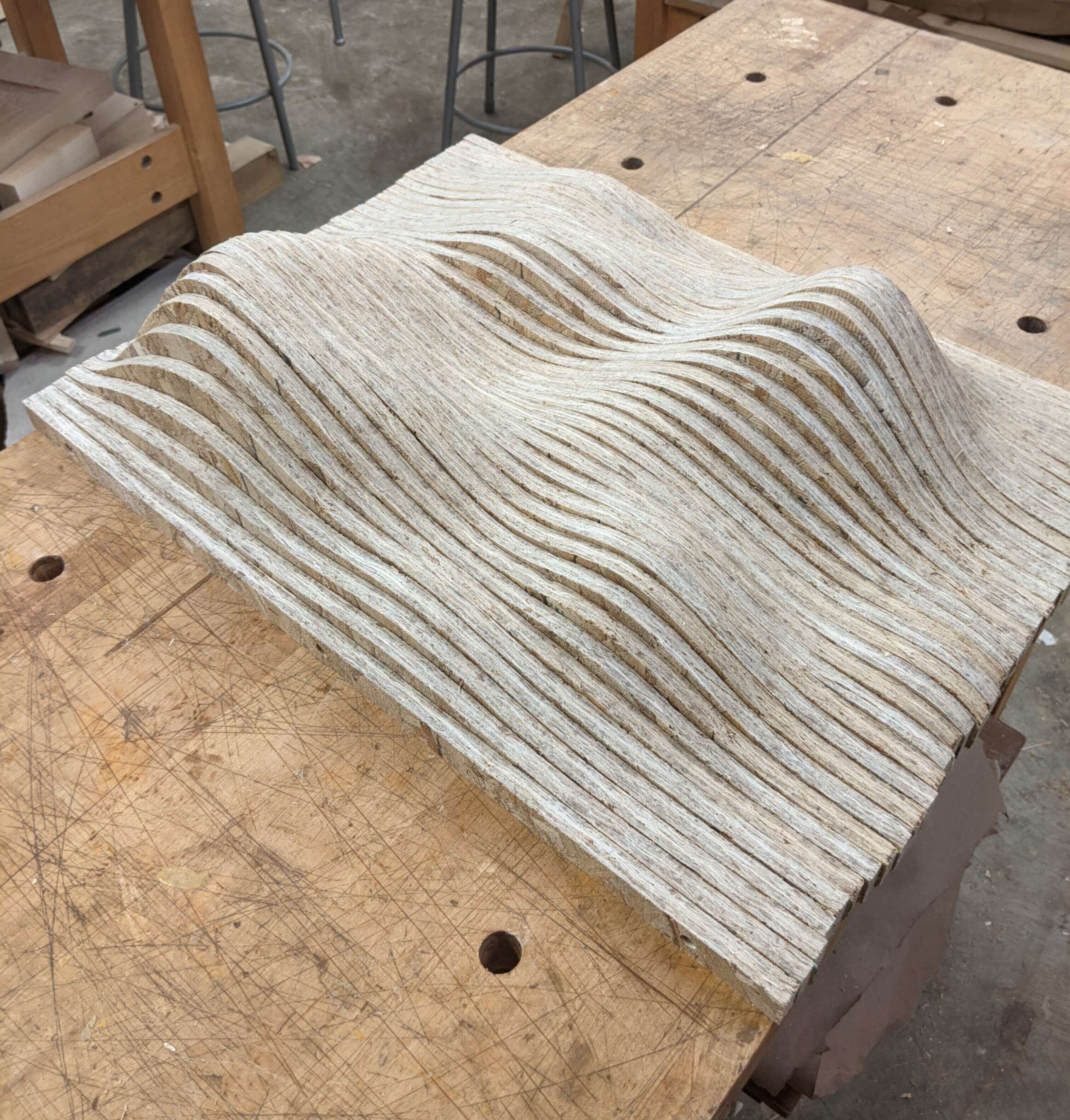

After the cutting was done, there was an onion skin left over on the bottom. I found that a box cutter to detach them out from the onion skin followed by a file to clean them up works pretty well. I had packed all the parts so closely that this was all that was left over of the OSB sheet:

After arranging them and putting them together for the first time:

And then finished: