Laser and Vinyl Cutting

09/22/2021

cut something on the vinylcutter

design, lasercut, and document a parametric construction kit,

accounting for the lasercutter kerf,

which can be assembled in multiple ways,

and for extra credit include elements that aren't flat

This is the first week we actually get to do something physical. The assignment this week is a double one:

It took me a while to come up with an idea but I eventually stumbled on something. I like the idea of swarm or modular systems, so I wanted to make something that I could make a bunch of. That led me pretty quickly to doing a bunch of origami cubes on the vinyl cutter. After a while I decided that making cardboard katanas would be pretty cool.

Laser Cutter Swords

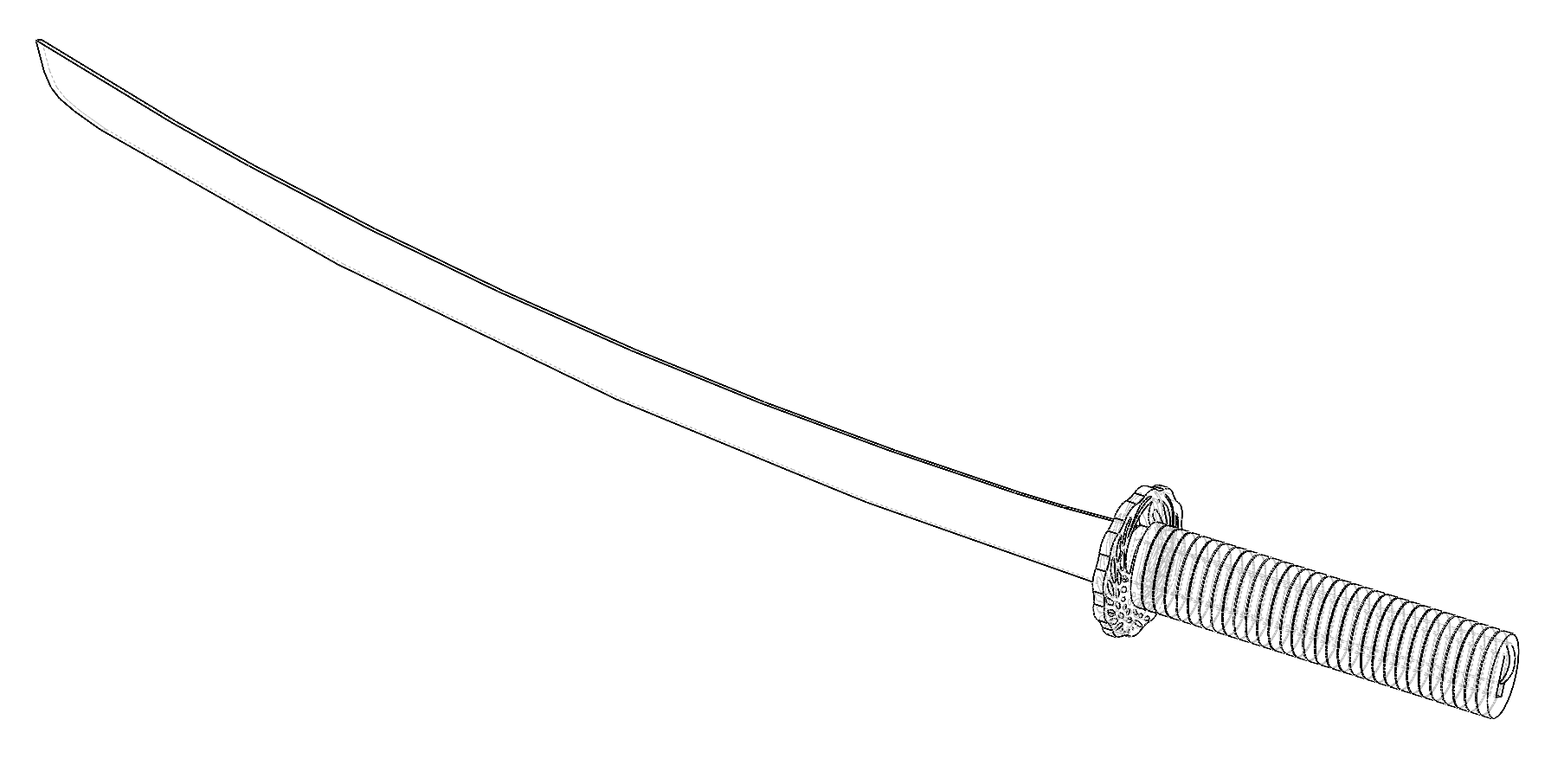

The profile of the sword was made by tracing out an image of a katana I found online. The parametric part of the file is the length of the handle which adjusts the amount of the little handle pieces that must also be cut.

The guard, or tsuba, I made by using SolidWorks' Auto-Tracing feature on an image of a heron I found online. The result was then cleaned up a bit and inserted into an assembly where I can see how the blade, handle, and tsuba all fit together.

I made an Assembly in SolidWorks just to make sure that everything works. Unfortunately, moving from SolidWorks to laser cutting was annoying. I'm sure there is a better way though.

- Download each SolidWorks component as a DXF file

- Import each of them into Inkscape

- Arrange how I want them to be cut on the Laser Cutter

- Realize that the laser cutting computer doesnt have Inkscape

- Import the Inkscape file into Rhino

- Scale the file to size

- Cut

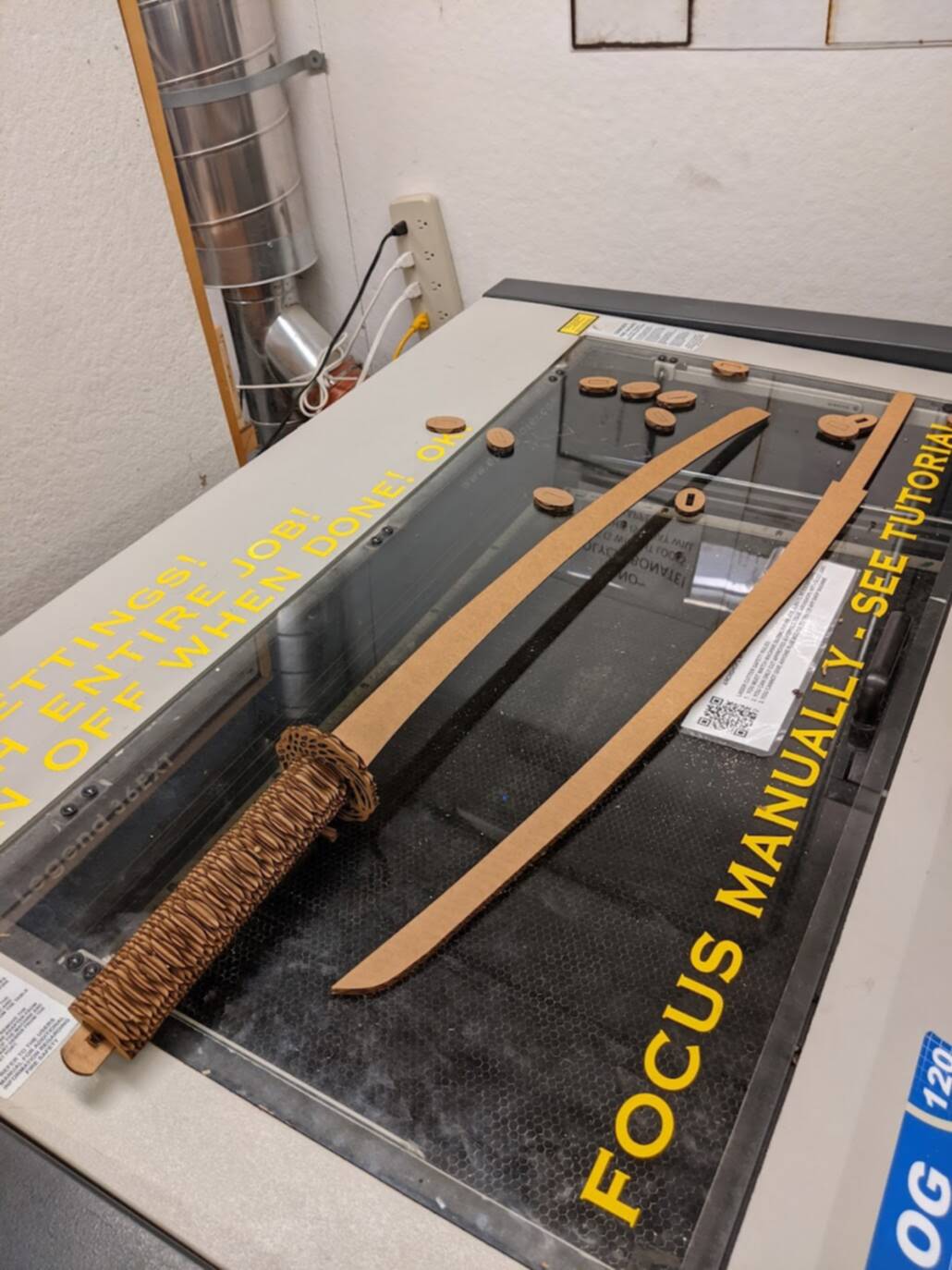

Before cutting and using an entire sheet of cardboard, I wanted to test the handle pieces to make sure that they would fit over the hilt nicely. So I made some mockup files and did the process above with them. This gave me:

They slid on well, tight enough that they don't wobble but not so tight that they are a pain to get on.

Eventually I get it cut and after popping out 40 of the handle pieces you get a sick looking sword

After cleaning it up a bit

They are super fun to swing around, but if you accidentally crease it at all, the sword just bends at that point and is ruined. I want to experiment with strengthening them with wood glue so that they can last longer. I'm also pretty sure that I can make at least three or four out of one sheet of cardboard.

Vinyl Cutter Cubes

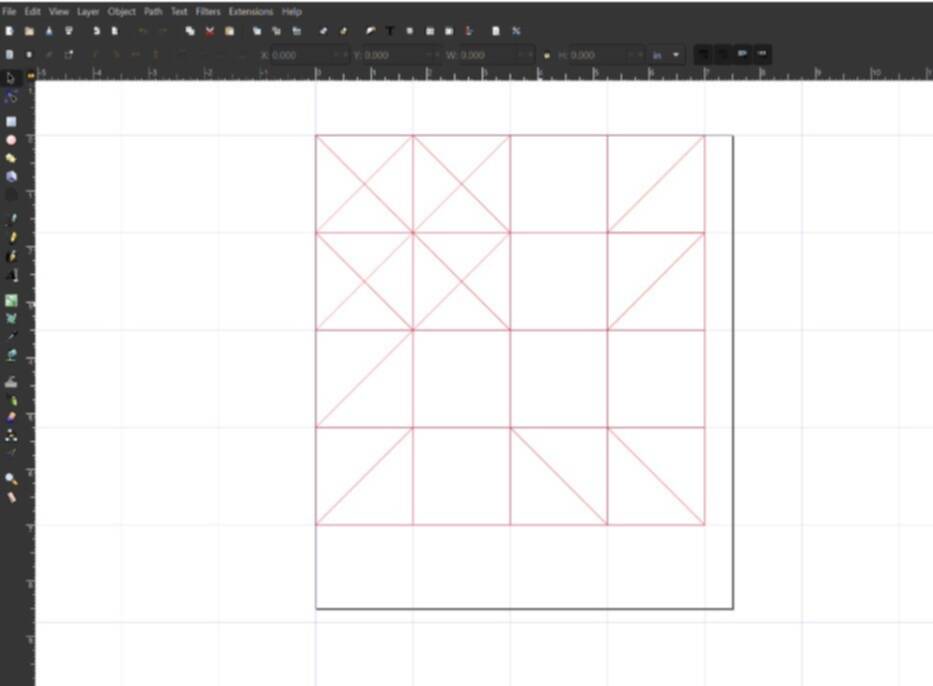

First to make these cubes I would have to find a source for the pattern for the cube. This video worked out pretty well for my needs. To get a 2D pattern of the cuts I needed to make I followed the tutorial and then unfolded the cube and traced out the pattern of lines in Inkscape. It took me multiple attempts to follow the tutorial well enough to get the clean unambiguous lines I needed to make a correct file.

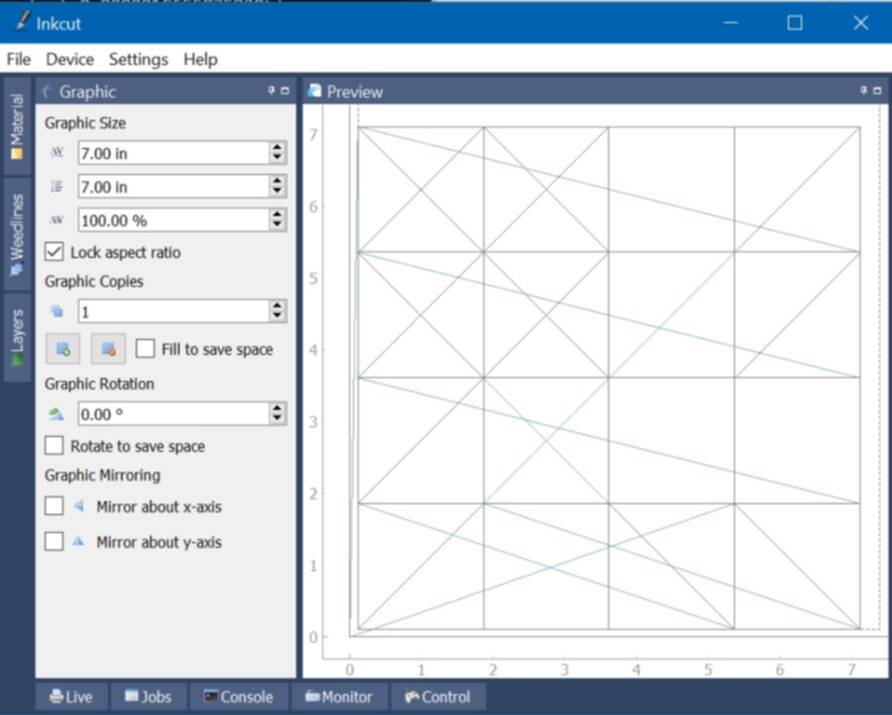

I didn't really pay attention in class for how to move from inkscape to the vinyl cutter, so I found online that people used some software called InkCut. So I downloaded that and a driver for the Roland Camm-1 cutter so I could run it directly from my laptop. After loading my file into InkCut I got:

Cutting the Paper

Actually cutting the thing was a pain in the butt. I had to adjust the force each iteration to make sure that I was getting a proper crease but not going all the way through. I ended up doing 70 force for creasing and 100 force for cutting. I can't remember what other setting I had, probably default, but if you are reading this to help yourself out, just test it.

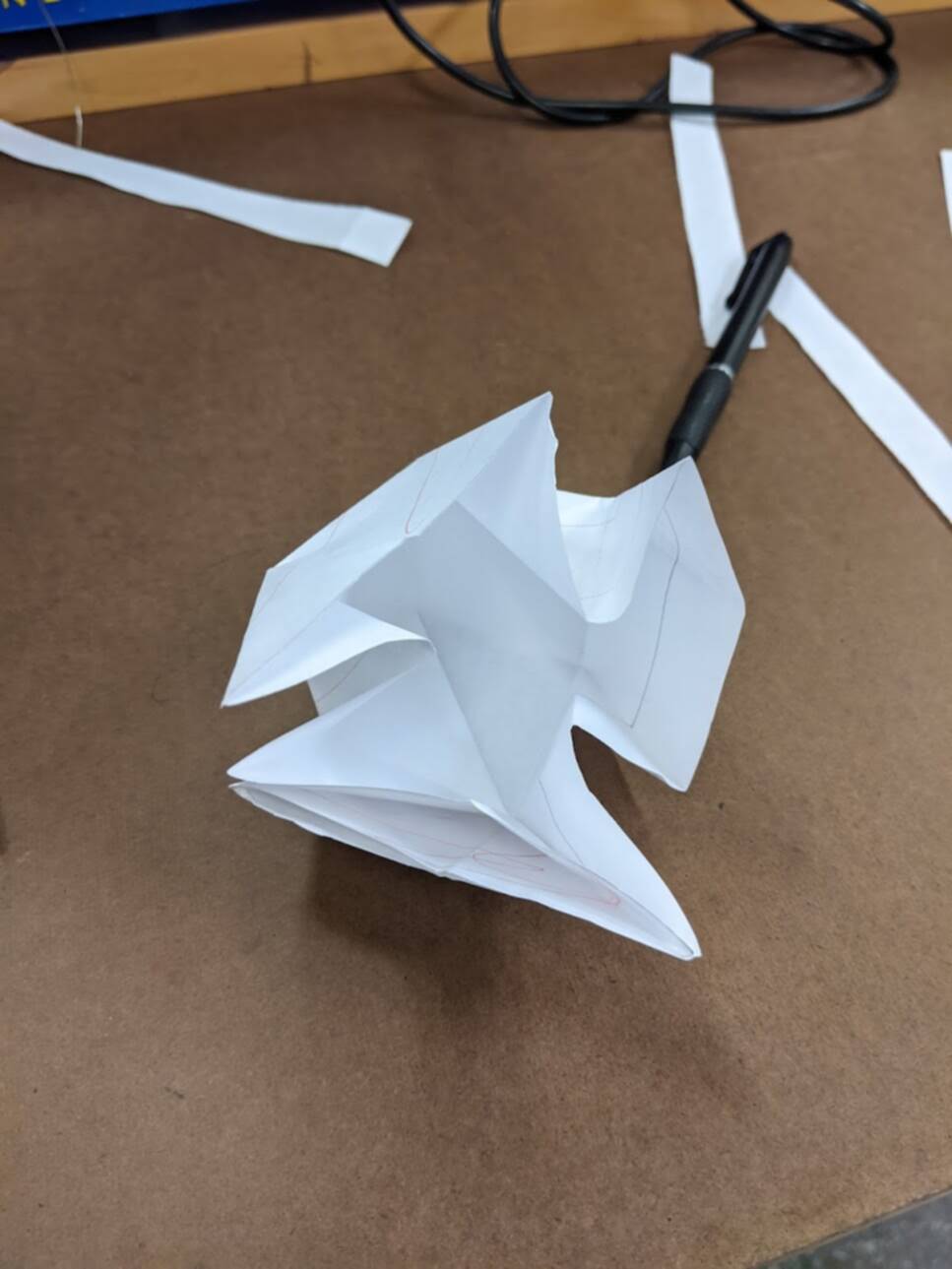

Over time I got faster at folding them. At the end I think I could make up to 20 an hour. Here's an image of one that's about to be finished.

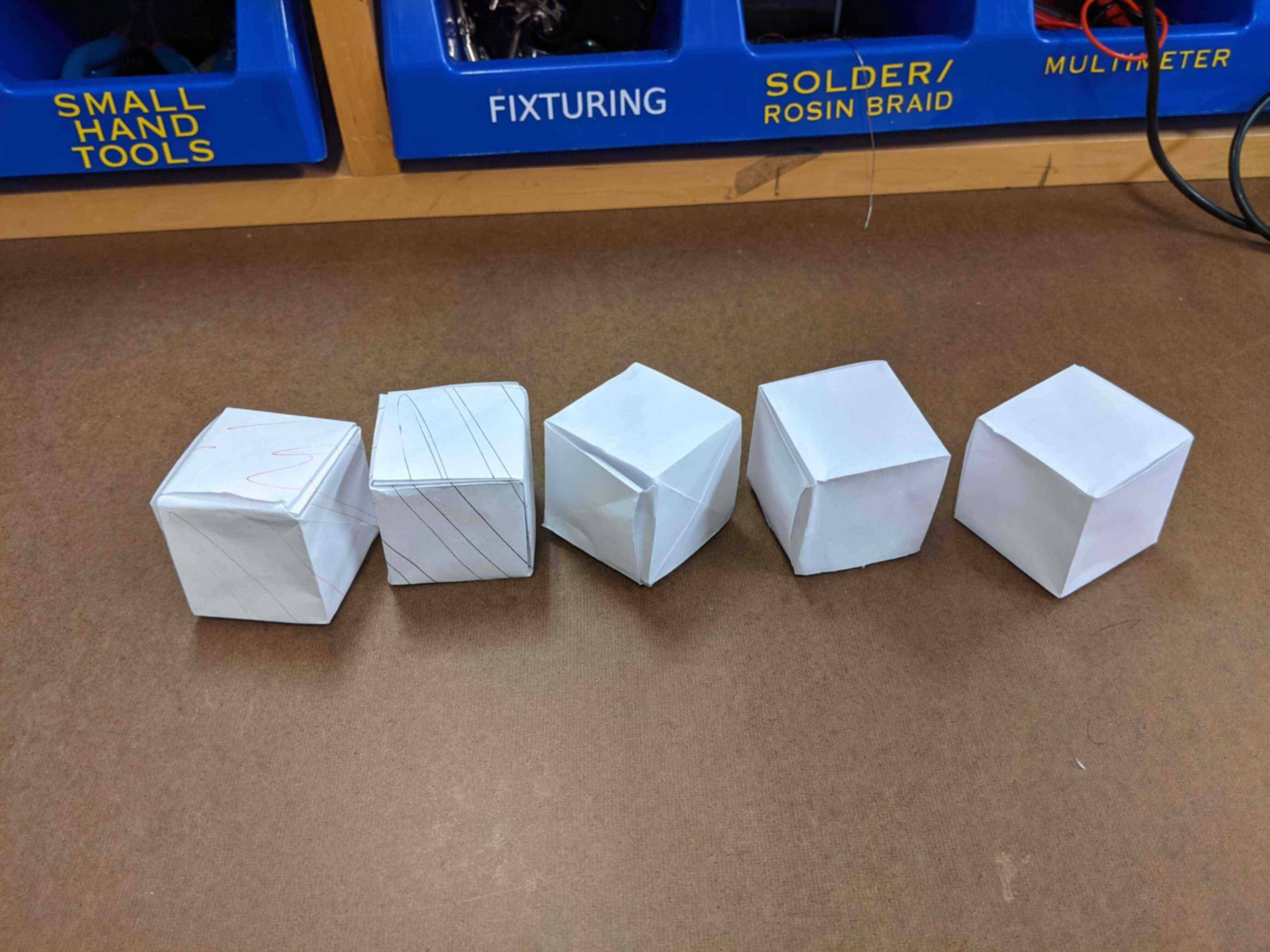

You can tell that the lines and the creases got better over time. Out of curiousity, I put them all next to each other and they were strong enough to hold up my laptop.